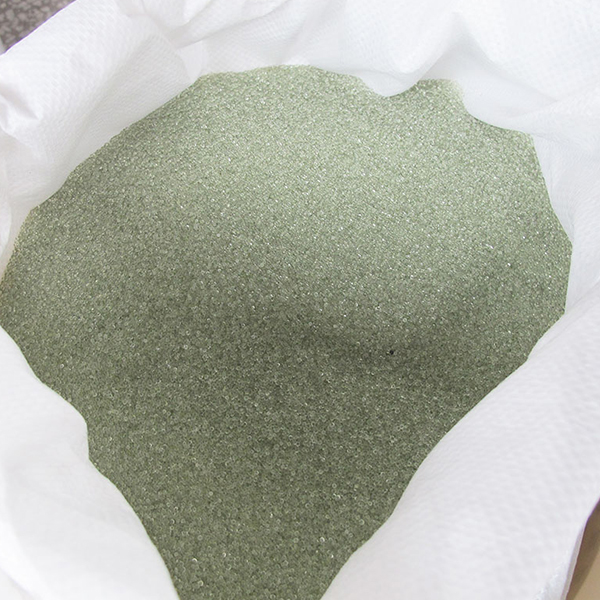

Sandblasting (shot) glass microspheres

Compressed air is used as the power source to form a high-speed jet beam that propels glass beads onto the surface of the workpiece to be treated, altering the appearance or shape of the workpiece surface. Due to the impact of the glass beads on the workpiece surface, the workpiece achieves a certain level of cleanliness and different roughness, improving its mechanical properties and thus enhancing its fatigue resistance. It provides a controllable rough surface to the part, increasing adhesion between it and the coating, extending the durability of the coating, and facilitating the leveling and decoration of the paint. It offers various degrees of surface effects.

Our factory can customize and produce glass microsphere products of various specifications, such as reflective glass beads and marking glass beads, according to different national and regional standards and customer requirements, including European EN1423 and 1424, American AASHTO M247, British BS6088, Japanese JIS R3301, and Korean KS L2521.